Innovative Furniture Production Techniques Unveiled

Share

The furniture production industry is undergoing a profound transformation, driven by the adoption of innovative manufacturing techniques that prioritize efficiency, precision, and sustainability. Automation integration, sustainable material sourcing, and streamlined operations are key factors in this evolution. Additionally, creative solutions for electric boxes, bespoke cabinet covering designs, and eco-friendly Vietnamese plywood options are revolutionizing the sector. Furthermore, modernized quality control processes leveraging digital technologies and data-driven approaches guarantee high-quality products and exceed customer expectations. As the industry continues to push boundaries, new production techniques are being revealed, opening up unprecedented possibilities for furniture makers and consumers alike.

Key Takeaways

• Automation integration streamlines furniture production, improving product quality and reducing waste.

• Sustainable materials are increasingly adopted to minimize the industry's environmental footprint.

• Digital technologies and data-driven approaches modernize quality control processes, ensuring high-quality products.

• Innovative cabinet covering designs conceal electric boxes in style, balancing aesthetics and practicality.

• Vietnamese plywood offers eco-friendly, customizable, and competitively priced solutions for furniture makers.

Evolution of Furniture Manufacturing

The furniture manufacturing industry has undergone a significant transformation over the years, shifting from traditional craftsmanship to technology-driven production processes that prioritize efficiency, precision, and sustainability.

This evolution has been driven by the need to reduce production costs, minimize waste, and meet growing consumer demand for eco-friendly products.

Automation integration has played a key role in this transformation, enabling manufacturers to streamline their operations and improve product quality.

Additionally, the increased adoption of sustainable materials has reduced the industry's environmental footprint.

By leveraging these advancements, furniture manufacturers can now produce high-quality, sustainable products that meet the needs of a rapidly changing market.

As the industry continues to evolve, we can expect to see even more innovative solutions emerge.

Creative Solutions for Electric Boxes

Five ubiquitous yet aesthetically unappealing elements in modern homes are electric boxes, which necessitate creative concealment to maintain a visually pleasing atmosphere. To address this issue, innovative furniture production techniques have given rise to artistic concealment methods that prioritize both form and function.

Here are three creative solutions for electric boxes:

-

Stylish camouflage: Incorporate electric boxes into floating shelves displays, seamlessly blending functionality with visual appeal.

-

Functional solutions: Design cabinets with hinged artwork or mirrors, providing easy access to the electric box while maintaining a stylish facade.

-

Practical designs: Strategically place furniture in front of the electric box, cleverly hiding it from view while ensuring effortless access.

These clever solutions strike a perfect balance between aesthetics and practicality, allowing homeowners to enjoy a clutter-free living space without compromising on functionality.

Innovative Cabinet Covering Designs

Moreover, incorporating cabinets into electric box concealment strategies involves innovative designs that now focus on creating bespoke cabinet covering solutions that seamlessly integrate with room decor while ensuring effortless access to the panel.

These customizable solutions cater to diverse tastes and spatial constraints, offering hidden compartments and clever storage options. By cleverly designing cabinets with sliding or hinged doors, users can easily access the electric panel without compromising the aesthetic appeal of the room.

Additionally, designers can incorporate subtle design elements, such as ornate hardware or textured finishes, to create a cohesive look that complements the surrounding environment.

With innovative cabinet covering designs, homeowners can now conceal electric boxes in style, enjoying a clutter-free and visually appealing space.

Vietnamese Plywood for Furniture Makers

Vietnam's thriving wood processing industry yields an array of high-quality plywood products, tailored to meet the specific demands of furniture makers. This Southeast Asian country has become a go-to destination for sourcing sustainable and affordable plywood.

Here are three reasons why Vietnamese plywood is a top choice for furniture makers:

-

Sustainable sourcing: Vietnam's plywood manufacturers prioritize eco-friendly practices, ensuring that their products meet international environmental standards.

-

Custom finishes: Vietnamese plywood can be finished with a wide range of coatings, from matte to glossy, to suit any design aesthetic.

-

Competitive pricing: Vietnamese plywood offers an unbeatable combination of quality and affordability, making it an attractive option for furniture makers on a budget.

With its commitment to sustainability, customization, and cost-effectiveness, Vietnamese plywood is revolutionizing the furniture production landscape.

Modernizing Quality Control Processes

As the furniture industry continues to evolve, implementing digital technologies and data-driven approaches is crucial to modernize quality control processes and maintain consistency in meeting customer expectations and regulatory standards.

By leveraging automated inspections and digital analysis, manufacturers can streamline quality control processes, reducing the risk of human error and increasing efficiency. This allows for real-time monitoring and detection of defects, enabling swift corrective action to be taken.

Additionally, digital analysis enables data-driven insights, facilitating continuous improvement and refinement of quality control processes. By embracing these innovative approaches, furniture manufacturers can guarantee the production of high-quality products that exceed customer expectations, while also reducing costs and improving overall business performance.

Frequently Asked Questions

What Are the Benefits of Using 3D Models in the Design Phase?

In the design phase, utilizing 3D models enhances Design Efficiency by allowing for Virtual Visualization, reducing errors, and streamlining the process, ultimately resulting in cost savings, improved accuracy, and increased customer satisfaction.

Can Furniture Manufacturers Use Recycled Materials for Production?

"A treasure trove of eco-friendly opportunities awaits! Furniture manufacturers can revolutionize material sourcing by incorporating recycled materials into their supply chain, reducing waste and environmental impact while creating unique, sustainable pieces that appeal to the eco-conscious consumer."

How Do Manufacturers Ensure Consistent Quality Across Production Batches?

To maintain consistent quality across production batches, manufacturers employ rigorous Quality Control measures, including batch testing, where random samples are inspected for defects, and dimensional accuracy, to guarantee uniformity and excellence in every piece of furniture produced.

Are There Any Specific Regulations for Furniture Manufacturing in Different Countries?

In the domain of furniture manufacturing, countries establish distinct regulations, requiring adherence to global standards and acquisition of regional permits, ensuring compliance with varying safety, environmental, and quality norms.

Can Furniture Be Designed for Adaptive Reuse or Repurposing Later On?

"Imagine a world where furniture is designed to be reincarnated, not retired! Yes, adaptive reuse is possible through design flexibility, ultimately paving the way for sustainable futures, where yesterday's chair becomes tomorrow's coffee table, and the cycle repeats."

Related Posts

-

Streamlined Kitchen Sink Organization Solution

A streamlined kitchen sink organization solution must balance functionality with aesthetics. A well-designed system s...

-

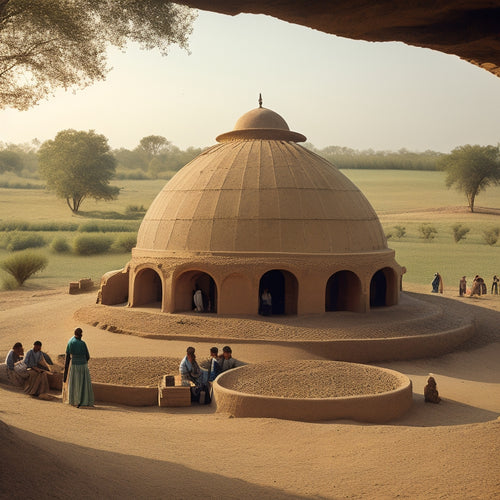

Transformative Techniques and Innovations in Mud Building

You're about to discover the cutting-edge of mud building, where ancient techniques meet modern innovations. Revoluti...