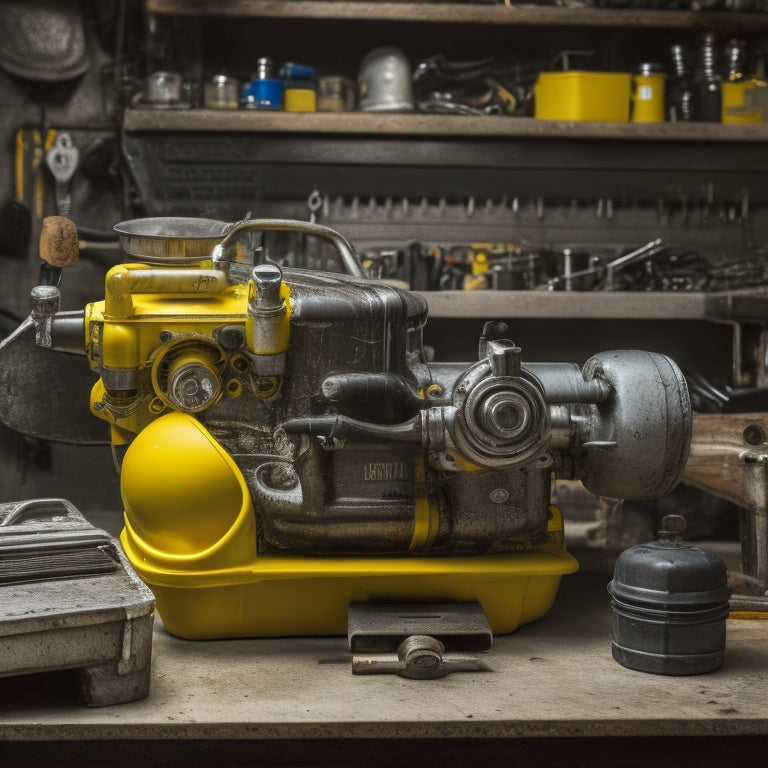

Johnson Outboard Engine: Choke Troubles Addressed

Share

Proper choke function is crucial to the overall performance of a Johnson Outboard Engine, and addressing choke troubles requires a thorough understanding of the engine's fuel system and carburetor components. Failure to address choke issues can lead to poor engine performance, decreased efficiency, and even engine failure. To troubleshoot choke troubles, inspect the choke adjustment, fuel filter, and carburetor for blockages or restrictions. A well-maintained fuel system and carburetor are essential for smooth engine operation. By understanding the intricate relationships between these components, you can uncover the root cause of choke troubles and implement effective solutions.

Key Takeaways

• Choke troubles can be addressed by identifying and resolving fuel system and carburetor issues in your Johnson Outboard Engine.

• Check choke adjustment for smooth engine operation, as faulty adjustment can cause starting problems.

• Inspect fuel system for blockages or restrictions that may be contributing to choke troubles.

• Regular cleaning and replacement of worn-out parts, such as the fuel filter, can improve engine efficiency and prevent choke issues.

• Ensure proper fuel flow by maintaining the recommended fuel mixture of 24:1 gas to TCW-3 rated oil for your 1963 Johnson Outboard Engine model.

Engine Maintenance Essentials

Proper maintenance is essential for the peak performance and longevity of the 3Hp Johnson outboard engine. Regular checks on specific components such as the fuel filter, carburetor, and water pump impeller are necessary to identify and address potential issues before they escalate.

Conducting a choke inspection is important to ensure top-notch engine performance. During this process, inspect the choke for any signs of wear or damage, and clean or replace it as needed.

Additionally, fuel system maintenance is critical to prevent fuel-related issues. Regularly check the fuel filter and ensure proper fuel flow to the carburetor. A clogged fuel filter can lead to engine failure, making it essential to address this aspect of maintenance.

Component Replacement Strategies

When replacing components in the 3Hp Johnson outboard engine, a strategic approach can help minimize downtime and guarantee a successful repair, particularly when addressing choke troubles.

A carburetor rebuild is often necessary to resolve issues, and using a new kit from a reputable dealer, such as Bombardier, is recommended. Additionally, coil replacement may be required to ensure proper timing, with replacement coils available for purchase at around $17 USD each.

It is vital to replace the cork float during the rebuild process to prevent sinking issues.

Performance Optimization Tips

Optimizing the performance of the 3Hp Johnson outboard engine requires attention to specific components, including the carburetor and fuel system, which can greatly impact engine efficiency and overall boat performance.

A precise choke adjustment is vital to guarantee proper air-fuel mixture, which in turn affects engine performance. The recommended fuel mixture for the 1963 model is 24:1 gas to TCW-3 rated oil.

A well-maintained carburetor, free from varnish buildup, is essential for peak engine performance. Regular cleaning and replacement of worn-out parts, such as the cork float, can considerably improve engine efficiency.

Troubleshooting Common Issues

Choke troubles, a common affliction in 3Hp Johnson outboard engines, can be effectively addressed by identifying and resolving underlying issues in the fuel system and carburetor.

To troubleshoot common issues, start by checking the choke adjustment, making sure it is properly set to allow for smooth engine operation. Starting problems can often be traced back to faulty choke adjustment or clogged fuel lines.

Inspect the fuel system for blockages or restrictions, and clean or replace components as necessary. Additionally, inspect the carburetor for signs of wear or damage, and perform routine maintenance tasks such as cleaning and rebuilding to prevent varnish buildup.

Community Insights and Advice

In the pursuit of maintaining a reliable 3Hp Johnson outboard engine, collective wisdom from experienced users and mechanics underscores the significance of adhering to regular maintenance schedules and addressing issues promptly to prevent minor problems from escalating into costly repairs.

The community emphasizes the importance of troubleshooting techniques, such as identifying and addressing varnish build-up, replacing worn-out parts, and ensuring proper fuel flow.

Community support is essential in sharing experiences, tips, and collaborative problem-solving, which contributes to a helpful community.

Frequently Asked Questions

How Often Should I Check and Clean the Spark Plugs?

For peak engine performance and safety, inspect spark plugs every 50-100 operating hours, cleaning or replacing them as needed. Confirm spark plug wires are secure, and perform fuel filter maintenance to prevent fuel contamination and ignition system issues.

What Are the Signs of a Failing Crankshaft Seal?

As the crankshaft rotates, a failing seal whispers warnings of impending doom, manifesting as a faint oil slick on the bilge, accompanied by a subtle crankshaft wobble, signaling seal failure and potential catastrophic engine damage.

Can I Use Synthetic Oil in My Johnson Outboard Engine?

When considering synthetic oil for your outboard engine, keep in mind that it offers superior lubrication, corrosion protection, and fuel efficiency benefits. Make sure compatibility by selecting an oil type specifically designed for marine use, such as TCW-3 rated oil.

How Do I Diagnose a Faulty Ignition Switch?

To diagnose a faulty ignition switch, inspect the ignition wires for signs of wear or corrosion, and utilize a spark tester to identify any ignition system issues, ensuring a safe and reliable diagnosis to prevent electrical shock hazards.

Is It Safe to Run My Engine at Maximum RPM for Extended Periods?

Operating an engine at maximum RPM for extended periods can compromise engine durability and potentially lead to premature wear or failure. Adhere to recommended RPM limits to guarantee safe and peak engine performance.

Related Posts

-

Family Harmony Achieved: Doral Home Renovation Unveiled

We designed our Doral home renovation around a simple yet powerful idea: that a unified, open space can bring our fam...

-

Transform Your Bathroom to Boost Home Sales

When you transform your bathroom into a serene oasis, you're not just making it look pretty - you're tapping into buy...

-

LYNK PROFESSIONAL: Transform Your Under-Sink Storage

Transform your under-sink storage with LYNK PROFESSIONAL, a cleverly designed system that tackles common challenges. ...