Mastering E3D V6 Hotend Assembly Guide

Share

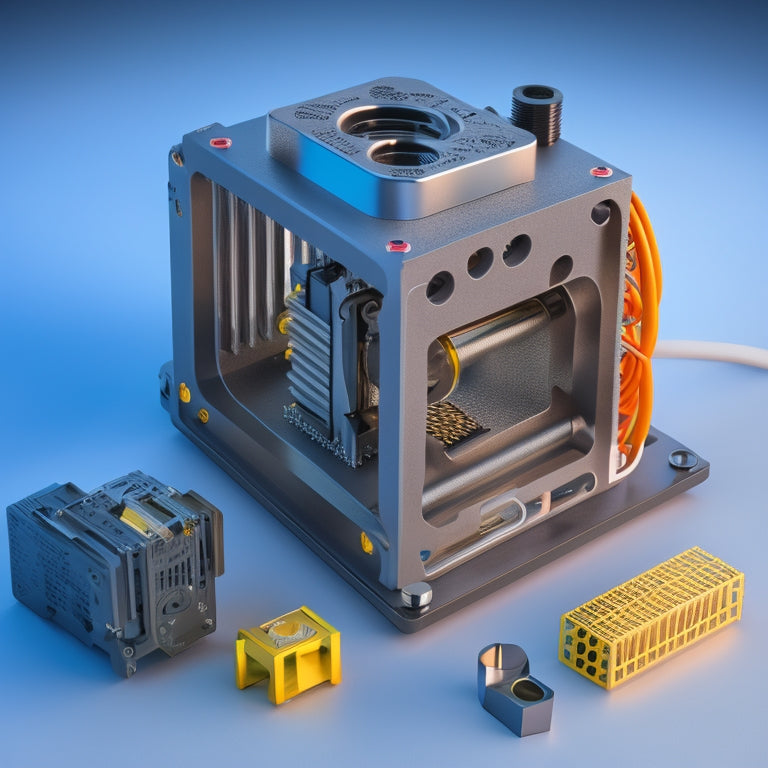

Mastering the E3D V6 hotend assembly requires a methodical approach, focusing on precise component installation and configuration. Proper nozzle alignment, correct heater cartridge installation, and understanding individual components are essential. Next, attention turns to PTFE tubing and fan installation, ensuring secure connections and efficient cooling. Finalizing the hotend assembly involves attaching the silicone sock and configuring firmware settings. By following these guidelines, peak 3D printing performance can be achieved. To tap into the full potential of your E3D V6 hotend, a deeper understanding of these critical assembly steps is vital for success.

Key Takeaways

• Ensure proper nozzle alignment for optimal hotend performance and prevent damage to the assembly.

• Correctly install the heater cartridge and thermistor to maintain accurate temperature control and prevent overheating.

• Securely attach PTFE tubing to the hotend to prevent leaks and ensure efficient heat dissipation.

• Configure firmware and settings accurately to accommodate the new hotend, including PID tuning and slicer settings adjustments.

• Regularly inspect and maintain the hotend assembly to prevent clogs, damage, and temperature inaccuracies.

E3D V6 Hotend Assembly Essentials

The E3D v6 All-Metal HotEnd assembly requires careful attention to detail and a thorough understanding of the individual components. Improper installation can lead to subpar performance, reduced lifespan, or even complete failure of the hotend. Proper nozzle alignment is essential, ensuring the nozzle is securely seated and tightened to prevent thermal runaway.

The heater cartridge, a critical component, must be installed correctly to avoid damage or electrical shorts. A well-executed installation begins with a solid understanding of these fundamental elements. By following precise guidelines and avoiding common pitfalls, you'll be well on your way to a successful E3D v6 HotEnd assembly.

PTFE Tubing and Fan Installation

With the heater cartridge and thermistor properly installed, attention turns to securing the PTFE tubing and fan assembly, a critical component of the E3D v6 All-Metal HotEnd.

Proper fan ducting is essential to guarantee efficient cooling and peak performance. To achieve this, apply tension to lock the PTFE tubing securely in the hotend, making sure it's not too loose or too tight.

Next, attach the 30mm fan and fan duct using Plast-Fast screws, positioning the fan wiring carefully. Secure the fan duct onto the hotend, making sure it covers the heatsink fin closest to the heater block.

Finalizing the HotEnd Assembly

Before finalizing the hotend assembly, make sure the hotend has cooled to a safe temperature, as excessive heat can damage the silicone sock or other components.

Now, it's time to attach the silicone sock. Confirm proper sock attachment by seating the sock clips securely onto the heater block. For Pro sock users, double-check the nozzle protrusion to make sure it's within the recommended 1-2mm range. For Normal sock users, ensure the sock is properly seated and adjusted.

A well-fitted sock is essential for excellent hotend performance and longevity. Take your time, and don't rush this step – a little patience will pay off in the long run.

With the sock securely in place, your E3D v6 hotend assembly is now complete, and you're ready to move on to the next stage.

Configuring Firmware and Settings

Following successful hotend assembly, attention turns to configuring firmware and settings to optimize the E3D v6 All-Metal HotEnd's performance.

Firmware customization is essential, so update your Marlin, Repetier, or RepRap Firmware according to the provided guides. For Marlin, update the Configuration.h file to accommodate the new hotend.

Next, perform PID Tuning to guarantee ideal temperature control.

Slicer adjustments are also necessary, so update your settings for the correct nozzle diameter, retraction distance, and consider system type and tube length.

Don't forget to adjust your extruder settings, such as temperature, flow rate, and acceleration, to get the most out of your E3D v6.

With these configurations in place, you'll be ready to print with precision and accuracy.

Troubleshooting and Maintenance Tips

During the operation of the E3D v6 All-Metal HotEnd, users may encounter issues that can be resolved through troubleshooting and preventative maintenance, thereby ensuring peak performance and longevity of the hotend. To minimize downtime, it's essential to familiarize yourself with common issues and their solutions.

| Common Issue | Troubleshooting Technique | Maintenance Tip |

|---|---|---|

| Clogged Nozzle | Clean with a drill bit or replace | Regularly clean the nozzle to prevent clogs |

| Temperature Inaccuracy | Check thermistor connection and calibration | Perform regular temperature calibration checks |

| Heater Block Damage | Inspect for signs of wear and replace if necessary | Handle the heater block with care to prevent damage |

| PTFE Tubing Damage | Inspect for signs of wear and replace if necessary | Handle PTFE tubing with care to prevent damage |

| Hotend Leaks | Check for loose connections and tighten | Perform regular checks for loose connections |

Frequently Asked Questions

Can I Use a Different Thermistor With the E3D V6 Hotend?

Did you know that 75% of 3D printing issues stem from temperature control? When it comes to Thermistor Options for the E3D v6 hotend, compatibility is key; stick to E3D-recommended thermistors or guarantee precise Thermistor Compatibility to avoid temperature inaccuracies and printing woes.

How Often Should I Clean the Hotend Nozzle and Heater Block?

To maintain peak print quality, clean the hotend nozzle and heater block every 3-5 prints or when noticing nozzle corrosion, using a soft brush and gentle cleaning solution to prevent damage and guarantee consistent performance.

Are There Any Specific Hotend Assembly Tools That I Must Have?

"Ah, the age-old question: can I assemble a hotend with a toothpick and prayer? Alas, no. Essential tools include a hotend wrench for precise nozzle tightening and a torque specification guide to avoid stripping those delicate threads."

Can I Upgrade My Old E3D V5 Hotend to the V6 Version?

When upgrading from E3D V5 to V6, verify hotend compatibility by checking thread sizes, nozzle diameters, and thermistor compatibility, then follow the recommended upgrade paths to avoid compatibility issues and guarantee a seamless shift.

Is It Necessary to Use Thermal Paste on the Heater Cartridge?

'A stitch in time saves nine' - indeed! Thermal paste on the heater cartridge is essential for peak heater efficiency and thermal performance, ensuring effective heat transfer and minimizing thermal resistance, thereby preventing hotspots and prolonging hotend lifespan.